October. 28, 2025

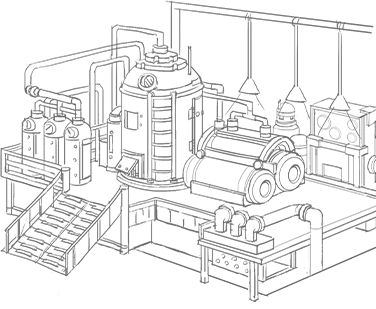

In industrial automation, selecting the correct type of switch is crucial for safety, efficiency, and reliability. Two commonly used types are limit switches and pressure switches. While both are essential in controlling machines and processes, they operate differently and serve distinct purposes. Understanding their differences can help engineers, technicians, and hobbyists choose the right switch for the right application.

A limit switch is an electromechanical device designed to detect the presence or position of an object. When an object makes physical contact with the actuator of the switch, it triggers a mechanical action, often opening or closing an electrical circuit. Limit switches are widely used in conveyor systems, elevators, and automated machinery to prevent over-travel, ensure precise positioning, and maintain operational safety.

Key Features of Limit Switches:

Mechanical actuator detects object movement.

Can handle repeated operations in harsh environments.

Provides precise positional feedback.

Often used as a safety interlock in machinery.

A pressure switch operates by monitoring the pressure of a gas or liquid within a system. When the pressure reaches a predefined threshold, the switch activates or deactivates an electrical circuit. Pressure switches are commonly found in HVAC systems, water pumps, hydraulic equipment, and pneumatic machinery.

Key Features of Pressure Switches:

Responds to pressure changes, not physical contact.

Adjustable setpoints for activation and deactivation.

Helps protect systems from overpressure or underpressure conditions.

Suitable for fluid or gas systems.

| Feature | Limit Switch | Pressure Switch |

|---|---|---|

| Detection Method | Mechanical contact | Pressure sensing |

| Application | Object position or movement | Fluid/gas pressure levels |

| Actuation | Plunger, lever, or roller | Diaphragm or piston |

| Use Cases | Conveyor end stops, safety interlocks | Pump control, compressor protection |

| Response Type | On/off position | On/off based on pressure threshold |

| Environmental Suitability | Harsh mechanical environments | Liquid or gas pipelines |

Limit Switch Applications:

Safety interlocks in industrial machinery.

Elevator door position sensing.

Conveyor belt end detection.

Robotic arm positioning.

Pressure Switch Applications:

Water pump control to maintain pressure levels.

Air compressor pressure monitoring.

Hydraulic system safety shutdown.

HVAC system pressure regulation.

When deciding between a limit switch and a pressure switch, consider the following:

Nature of the Detection: If your system requires detecting the physical position or motion of objects, a limit switch is ideal. For pressure monitoring in fluids or gases, a pressure switch is suitable.

Environment: Limit switches handle mechanical stress well. Pressure switches need compatibility with the fluid type and pressure range.

Accuracy Needs: Limit switches are precise for positional detection, while pressure switches are precise for threshold-based pressure detection.

Q1: Can a limit switch detect fluid pressure?

No, limit switches detect the position or presence of an object, not fluid pressure.

Q2: Can a pressure switch prevent machine over-travel?

No, pressure switches only respond to pressure changes, not physical positions.

Q3: Are limit switches suitable for hazardous environments?

Yes, many limit switches are designed for harsh industrial environments and can withstand dust, vibration, and moisture.

Q4: Can pressure switches be adjustable?

Yes, most pressure switches allow adjustment of the activation and deactivation pressure points.

Limit switches and pressure switches serve distinct but critical roles in automation and industrial systems. Limit switches excel at detecting object positions, ensuring mechanical safety, and providing precise motion feedback. Pressure switches, on the other hand, safeguard fluid or gas systems by monitoring pressure levels and activating circuits when necessary. Understanding their differences ensures the right choice for safer and more efficient operations.