October. 31, 2025

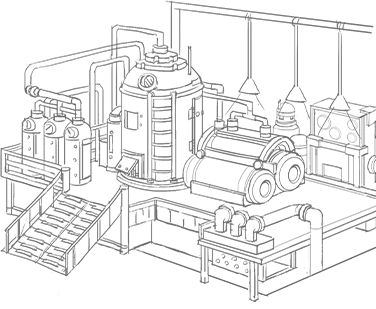

Limit switches are a fundamental component in industrial automation. Though they might appear simple, their role in machinery control and safety is indispensable. From elevators to robotic arms, limit switches ensure machines operate accurately and safely. In this article, we explore what a limit switch does, how it functions, and where it is applied.

A limit switch is an electromechanical device that detects the presence or position of an object. It works by physically interacting with a moving part, causing the switch to change the state of its electrical contacts. This action can start, stop, or reverse a machine or trigger an alarm.

The working mechanism of a limit switch involves several components:

Actuator: A lever, plunger, roller, or button that comes into contact with the object.

Electrical Contacts: Switch states change (open/close) when the actuator moves.

Housing: Protects the internal mechanism from dust, moisture, and mechanical damage.

When the actuator is pressed by a moving object, the internal contacts are toggled, sending a signal to the connected system. This signal can either halt movement, turn on a device, or trigger an alert, depending on the application.

Plunger Limit Switch: Uses a straight-moving plunger to detect motion.

Lever Limit Switch: Employs a lever arm that pivots when contacted.

Roller Limit Switch: The lever has a roller at the end, suitable for continuous motion detection.

Non-Contact Limit Switch: Uses proximity sensors instead of physical contact (modern variant).

Safety Protection: Prevents machinery from over-travel and potential damage.

Position Control: Ensures components stop or start at precise locations.

Automation Control: Initiates sequences in automated systems.

Alerting and Signaling: Provides feedback to operators when limits are reached.

Limit switches are versatile and used across many industries:

Industrial Machinery: Stops motors when parts reach designated positions.

Conveyors: Detects package or item positions.

Elevators: Ensures doors open/close properly and stops cars at correct floors.

Robotics: Helps robotic arms move accurately without collisions.

Safety Interlocks: Ensures guards and doors are closed before machine operation.

High durability in harsh environments.

Reliable mechanical feedback.

Simple installation and maintenance.

Cost-effective solution for positional sensing.

Q1: Can a limit switch control speed?

No, it primarily detects position or presence. Speed control requires other sensors or devices.

Q2: Are limit switches suitable for outdoor use?

Yes, many are designed with protective housings to withstand dust, moisture, and temperature variations.

Q3: Can limit switches be used in robotics?

Absolutely, they provide precise position feedback for robotic arms and automated machinery.

Q4: Do all limit switches require physical contact?

Traditional limit switches do, but non-contact versions use magnetic or optical sensing.

A limit switch is a small yet vital device in industrial automation and machinery safety. By detecting object positions, controlling sequences, and preventing over-travel, limit switches play a critical role in efficient and safe operations. Whether in a conveyor system, elevator, or robotic arm, their reliable performance makes them indispensable in modern industry.