What is a safety door switch? In short: it’s a device that monitors whether a door or protective guard is closed — and only allows a machine or equipment to run when that door is securely shut, cutting power or preventing operation the moment the door opens. As long as the door is closed, the switch keeps the control circuit closed; once the door opens (or the guard is removed), the switch immediately trips and shuts down the machine, preventing access to hazardous moving parts or dangerous areas.

How Does a Safety Door Switch Work

Basic Working Mechanism

A safety door switch (also known as a guard‑interlock switch or interlock switch) consists of two main parts: a switch body mounted on the fixed machine frame and an actuator mounted on the movable guard or door. When the door closes, the actuator engages the switch body, closing a normally‑closed (NC) contact — the machine sees this as “door closed, safe to run.” When the door opens, the NC contact opens, cutting power or signal to the machine and forcing it to stop.

Types of Safety Door Switches

Non‑locking interlock switches: allow the door to be opened at any time; once the door opens, the machine stops.

Locking interlock switches (spring‑lock or solenoid‑lock): these not only detect the door status but also mechanically lock the door while the machine runs — preventing opening until the machine stops.

Non‑contact (magnetic or RFID) interlock switches: use magnets or coded actuators rather than physical mechanical engagement. These avoid wear and tear and work better in dirty, dusty, or wet environments.

Non-contact types are especially useful in clean rooms, food‑processing equipment, or any setting where hygiene or minimal contamination is crucial.

Applications of Safety Door Switches

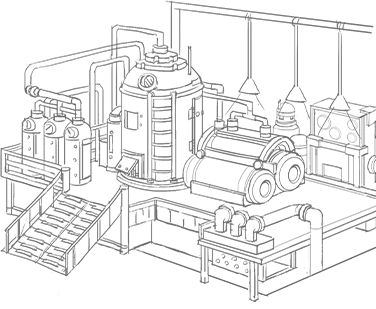

Industrial Machinery and Automation

Safety door switches are widely used on machine-tools, robotic cells, CNC machines, packaging lines and other automated equipment. They prevent machines from running when guards or access doors are open, protecting operators during setup, maintenance, or loading/unloading.

Maintenance, Servicing and Safe Access

Whenever maintenance or inspection is required — especially when moving parts, high voltage or hazards exist — the safety door switch ensures the machine cannot accidentally start. This safeguards maintenance staff and reduces human‑error risks.

Compliance with Safety Standards

Because safety door switches are a core part of guarding and interlocking systems, they help manufacturers comply with industrial safety standards and regulations — e.g., those requiring that machinery be immobilised if guards are opened.

Benefits of Installing a Safety Door Switch

Enhanced Operator Safety & Accident Prevention: The switch immediately stops machines when guards open, preventing exposure to dangerous moving parts.

Tamper-Resistant and Reliable: High-quality safety switches are designed with anti-tamper mechanisms such that they cannot be easily bypassed with screws, coins, or simple tools.

Reduced Wear and Maintenance (in Non‑Contact Types): Non‑contact versions avoid physical friction, making them suitable for clean or harsh environments and lowering maintenance needs.

Regulatory Compliance and Safety Certification: Many safety door switches comply with international standards (e.g., ISO 14119), making them compatible with safety-certified machinery designs.

Safety Locking vs Standard Safety Door Switch: What’s the Difference?

Some interlock switches simply detect the door status and stop the machine (non‑locking type). Others — locking interlock switches — add a mechanical lock to prevent the door from being opened while the machine runs, especially useful if the machine has inertia or cannot stop immediately.

Non‑locking interlock switch — suitable when the machine can stop immediately upon door opening.

Locking interlock switch (spring‑lock / solenoid‑lock) — needed when immediate stopping isn’t guaranteed, or when opening the door during operation poses a serious hazard.

For high‑risk machines with inertia or delayed stop, the locking type dramatically reduces risk of accidental access mid‑operation.

Choosing the Right Safety Door Switch for Your Needs

When selecting a safety door switch (e.g., from brand KACON), consider the following:

Type of actuation needed: mechanical vs magnetic vs RFID/non‑contact — depends on environment (clean room, dusty, wet, etc.).

Locking requirement: does the machine need a locked door when operating? If so, choose locking interlock (spring‑lock or solenoid‑lock).

Safety standards and certification: ensure the switch meets standards like ISO 14119 / IEC 60947‑5‑1.

Environment and durability: for harsh, dirty, or moisture-prone industrial settings, non‑contact or sealed (e.g., IP‑rated) switches perform better.

Maintenance and longevity: non‑contact switches tend to wear out less and reduce maintenance over time.

Installation and Maintenance Best Practices

Mount the switch body and actuator properly — ensure alignment so the actuator reliably engages when the door closes.

For locking interlock switches used on machines with inertia, ensure the machine has fully stopped before unlocking the door.

Conduct periodic inspections for wear, misalignment, debris, or tampering — especially in dust-prone or heavy‑use environments.

Maintain a log of inspections, repairs, and replacements to detect potential pattern of failures.

Why "KACON" Safety Door Switches Matter

As a brand offering robust safety interlock solutions, KACON understands that safety accuracy and reliability matter. A properly engineered KACON safety door switch — whether non‑locking or locking, mechanical or non‑contact — ensures that machinery only runs under safe conditions, reduces risk of accidents, and helps manufacturers meet global safety standards.

Conclusion

A safety door switch plays a fundamental role in safeguarding industrial machinery and protecting workers. By verifying that protective doors or guards remain closed (and locking them if necessary), these switches prevent machines from operating under unsafe conditions. Whether you work in manufacturing, automation, maintenance or any environment with hazardous equipment, installing a reliable safety door switch — such as those from KACON — increases safety, ensures regulatory compliance, and minimizes risk of costly accidents.