November. 24, 2025

A safety relay module is a critical device in industrial automation and machinery systems that ensures the safety of both equipment and personnel. What is a safety relay module? In essence, it monitors safety inputs such as emergency stops, light curtains, and door switches, and controls outputs to stop machinery or prevent hazardous operations when unsafe conditions are detected. KACON safety relay modules are engineered to provide reliable, fast, and fail-safe protection in a variety of industrial applications, helping companies comply with international safety standards and reduce the risk of workplace accidents.

A safety relay module is an electromechanical or solid-state device designed to monitor safety circuits and control outputs in response to abnormal or hazardous conditions. It acts as an intermediary between safety devices (like e-stops, light curtains, or safety mats) and machinery actuators. When a fault or unsafe condition is detected, the relay interrupts power to the relevant machinery, ensuring immediate shutdown or activation of protective mechanisms.

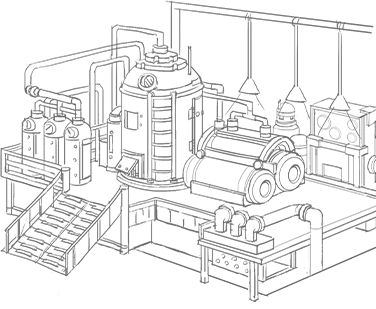

In machinery, safety relay modules serve as the backbone of safety control systems. They prevent accidental startup, unintended motion, and unsafe operation of equipment. For example, in a robotic assembly line, a safety relay module can detect if a protective door is open and instantly cut power to the robot, preventing injuries and equipment damage. KACON modules are designed to support such applications with high reliability and rapid response times, often under 20 milliseconds.

Safety relay modules work by constantly monitoring input signals from safety devices. When all monitored conditions are safe, the relay maintains an energized output state. If any unsafe signal is detected, the relay de-energizes the output, triggering an emergency stop or other protective actions. Advanced KACON models use dual-channel monitoring and cross-checking to comply with IEC 61508 and ISO 13849 standards, ensuring fault-tolerant operation and redundancy.

Safety relay modules come in various types:

Basic Safety Relays: Simple devices for emergency stop circuits or safety gates.

Time-Delayed Relays: Include programmable delays for processes requiring staged shutdown.

Advanced / Programmable Relays: Capable of monitoring multiple inputs, offering diagnostics, and integrating with PLC systems.

Choosing the right type depends on machinery complexity, safety requirements, and compliance standards.

While safety switches physically detect door openings or machine access, safety relay modules manage the logic and control actions based on multiple safety inputs. In high-risk industrial environments, modules like KACON relays provide superior reliability and flexibility compared to relying solely on switches, as they can integrate multiple inputs, provide diagnostic feedback, and ensure fail-safe responses.

Safety relay modules are widely used across industries, including:

Manufacturing lines with robotic arms

Presses, conveyors, and stamping machines

Chemical processing plants requiring emergency shutdown

Packaging machinery

KACON safety relay modules are engineered to operate reliably under harsh industrial conditions, such as high temperature, vibration, or dust exposure.

Data centers require rapid response safety devices to protect critical infrastructure. Safety relay modules can monitor emergency stop buttons, door locks, and environmental alarms, instantly shutting down equipment to prevent damage or electrical hazards. KACON’s compact modules are ideal for integration into control panels without occupying excessive space.

Common issues with safety relay modules include false trips, wiring errors, or degraded components. Troubleshooting involves:

Checking input devices for proper function (e.g., e-stop, door switch).

Verifying wiring integrity and correct connection to outputs.

Testing module response according to manufacturer specifications.

KACON provides detailed manuals and diagnostic LEDs to simplify troubleshooting.

Safety relay modules must comply with strict safety standards:

IEC 61508: Functional safety for electrical/electronic systems

ISO 13849: Safety of machinery and control systems

EN 60204: Electrical equipment of machines

KACON modules are certified to meet or exceed these standards, ensuring both regulatory compliance and operational safety.

KACON is a leading manufacturer of industrial safety devices, offering modules with high reliability, fast response, and versatile configurations. KACON safety relay modules are suitable for a wide range of applications, from simple emergency stops to complex automated production systems, providing comprehensive protection and peace of mind for operators and engineers alike.

Safety relay modules are essential components in industrial safety systems, providing real-time monitoring and fail-safe control of machinery and processes. By understanding the definition, function, types, applications, and standards, engineers and safety managers can select the appropriate KACON modules to ensure maximum protection for personnel and equipment. With robust design, compliance with international standards, and flexible integration options, KACON safety relay modules represent an optimal choice for industrial automation safety.