Solution Proposal

We specialize in KACON control foot switches, offering tailored configurations to meet your unique application needs. Whether you're in manufacturing, automation, or medical equipment, our expert team provides practical, cost-effective heavy duty foot switch solutions built to last.

From emergency stop switches to smart relays, each foot switch solution is engineered to enhance performance and ensure operational safety. Backed by decades of experience and advanced technology, KACON helps you build smarter, safer systems with reliable heavy duty foot switch solutions.

In today's highly automated industrial environments, precise, reliable, and safe human-machine interaction is crucial. Are you facing any of the following challenges?

Need to Improve Production Efficiency: Are operators' hands occupied, creating production bottlenecks?

Need to Manage Safety Risks: Do traditional manual switches pose safety hazards, requiring emergency stop mechanisms?

Special Application Scenarios: Do standard devices fail to meet requirements in harsh environments like sterile, explosive, high-dust, or humid conditions?

Optimizing Ergonomics: Are repetitive operations causing worker fatigue, affecting work quality and health?

Equipment Customization Needs: Can off-the-shelf products not perfectly integrate into your specialized equipment or workflow?

At KACON, we understand there is no "one-size-fits-all" solution. We are committed to listening to your specific needs and transforming challenges into actionable, efficient solutions.

KACON is not just a foot switch manufacturer; we are your trusted industrial control partner. Our solution approach focuses on delivering customized Heavy Duty Foot Switch Solutions that perfectly match your operational requirements. From initial consultation and system analysis to design, testing, and implementation, every step is tailored to ensure reliability, durability, and safety.

Our expert team will communicate deeply with you to understand in detail your:

Application Scenario: Equipment type, process flow, operating environment (temperature, humidity, IP rating).

Functional Requirements: Actuation method (single pedal, dual pedal, rocker), contact configuration (NO/NC), control signal type.

Safety Requirements: Emergency stop function, protection rating (e.g., IP67), certification standards (e.g., CE, UL).

Ergonomics: Pedal actuation force, size, material, and operational comfort.

Integration Requirements: Interface type, cable length, mounting method.

Based on the analysis, we will provide you with:

Product Selection Advice: Recommend the most suitable model from our extensive standard product portfolio.

Deep Customization Services: When standard products aren't sufficient, we offer services including structural modifications, custom circuitry, special materials (stainless steel, antibacterial plastic), logo engraving, custom cables and connectors.

Prototype & Testing: For complex needs, we can provide samples or prototypes for testing and validation.

We use high-quality materials and precision manufacturing processes to ensure every foot switch possesses:

Exceptional Durability: Ultra-long mechanical and electrical life, withstands millions of actuations.

Reliable Safety: Robust structural design ensures stable operation in harsh industrial environments.

Strict Quality Control: Multiple quality inspection processes from raw materials to finished products.

We provide timely technical support, adequate spare parts supply, and rapid after-sales response to ensure your production continues uninterrupted.

Choosing a KACON customized solution gives you:

Precise Match: Solutions designed specifically for your application, eliminating efficiency losses and risks from compromise.

Enhanced Efficiency: Frees operators' hands, optimizes workflows, directly boosting production efficiency.

Increased Safety: Built-in safety designs and emergency functions provide solid protection for your personnel and equipment.

Exceptional Durability: Reduces downtime caused by equipment failure, lowering the total cost of ownership.

Expert Partnership: You gain not just a product, but a team of experts with profound industry experience.

Our solutions have been successfully applied across numerous industries:

Manufacturing & Automation:

Welding Equipment: Hands hold the torch, foot controls current on/off.

Machine Tools: Controls start/stop for lathes, milling machines, punch presses.

Assembly Lines: Foot actuates testing or conveyance while hands are assembling.

Medical Equipment:

Surgical Devices: Enables sterile operation of electrocautery units, operating tables, microscopes.

Diagnostic Equipment: Operates X-ray machines, ultrasound systems, avoiding hand contact.

Packaging & Printing:

Packaging Machinery: Foot controls sealing, marking processes.

Printing Machinery: Controls jogging, resetting of printing presses.

Testing & Measurement:

Foot controls the start of test sequences while hands secure the test object.

Typical application scenarios

Scene 1: Welding workstation

Challenge: Welders need to hold both the welding torch and materials with both hands, making it impossible to switch them manually.

Plan: Use a heavy-duty foot switch to control the on/off of welding current.

Value: Enhance operational safety and welding efficiency, achieving precise control.

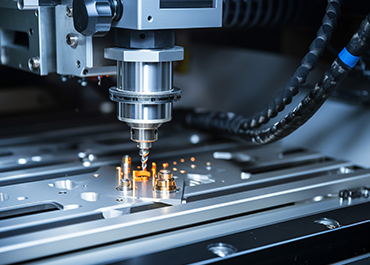

Scene 2: Industrial stamping equipment

Challenge: A reliable method is needed to activate a large press from a safe distance.

Solution: Configure a dual-pedal safety switch (which can only be activated by stepping on both pedals simultaneously) and link it with the Safety Relay Module.

Value: Significantly enhancing the intrinsic safety level of equipment and complying with safety production regulations.

Scene 3: Medical diagnostic equipment

Challenge: During examinations, doctors need to control equipment under sterile conditions.

Plan: Adopt a sealed and easy-to-clean industrial foot switch to control equipment operation.

Value: Ensuring a sterile environment and optimizing workflow processes.

Every great project starts with a conversation. Let's start discussing your needs!

Contact our solution experts now for a free initial consultation and proposal.

We guarantee all your information will be kept strictly confidential. Let's work together to create a safer, more efficient control experience for your business.